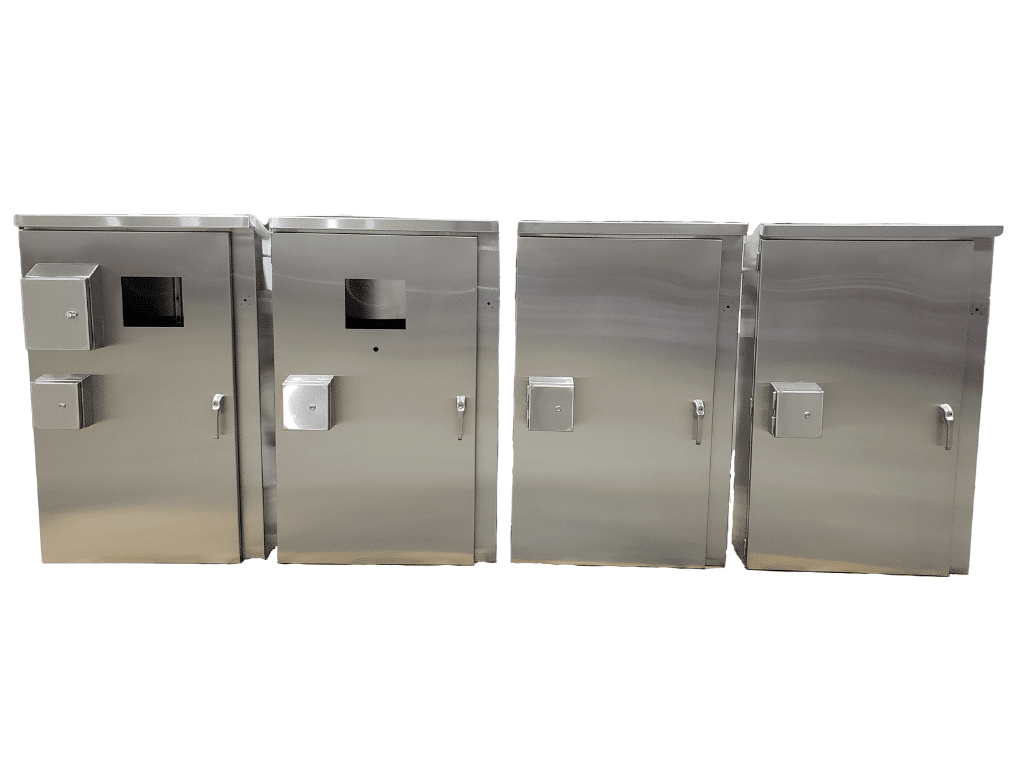

Hygienic Flanged Door Enclosures

Enhance the security and longevity of your essential equipment with the 4Xxtreme® Hygienic Flanged Single Door Enclosure. Engineered to meet Type 4X, IP66, and IP69K standards, these enclosures provide unmatched protection against water, dust, and other contaminants. This high level of protection ensures minimal equipment downtime and significantly reduces the total cost of ownership.

The inclusion of flanges adds an additional layer of sealing, enhancing the structural integrity and ensuring a more secure and reliable installation, which is crucial in preventing ingress and protecting sensitive equipment in any harsh environment.

Similar Products:

Hygienic Flanged Door Enclosures

Enhance the security and longevity of your essential equipment with the 4Xxtreme® Hygienic Flanged Single Door Enclosure. Engineered to meet Type 4X, IP66, and IP69K standards, these enclosures provide unmatched protection against water, dust, and other contaminants. This high level of protection ensures minimal equipment downtime and significantly reduces the total cost of ownership.

The inclusion of flanges adds an additional layer of sealing, enhancing the structural integrity and ensuring a more secure and reliable installation, which is crucial in preventing ingress and protecting sensitive equipment in any harsh environment.

Superior Design

Double Seal™ Gasketing Technology

- Field-replaceable gasket system

- Foreign material inspectable

Ultra Clean – Free Draining Design

- 7° Hygienic Pitch on all top and bottom of

doors - Pitched outer seal gasket for full drainage

- Weld-on bullet hinge assembly

- Lift-off door

- 180° door swing

- Manufactured from 14-gauge or 12-gauge 304 or 316 SS material

- All outside weld seams are continuously welded and ground smooth

Double Stud® Mounting Technology

- Innovative mounting system that eliminates gaskets and reduces overall installation time

Hygienic Pitched Top Configurations

- We offer the most extensive range of electrical enclosure top configurations in the industry

- Slope Forward (Slope 7° to 30°)

- Slope Back (7° to 22°)

- Bullnose Slope Forward (7° to 30°)

- Bullnose Slope Back (7° to 30°)

- Flat Top

Single 316 SS Three-Point Latching

- Hygienic quarter turn

- Master Defeater and Slave handles

Double Seal™ Gasketing Technology

- Field-replaceable gasket system

- Foreign material inspectable

Ultra Clean – Free Draining Design

- 7° Hygienic Pitch on all top and bottom of

doors - Pitched outer seal gasket for full drainage

- Weld-on bullet hinge assembly

- Lift-off door

- 180° door swing

- Manufactured from 14-gauge or 12-gauge 304 or 316 SS material

- All outside weld seams are continuously welded and ground smooth

Double Stud® Mounting Technology

- Innovative mounting system that eliminates gaskets and reduces overall installation time

Hygienic Pitched Top Configurations

- We offer the most extensive range of electrical enclosure top configurations in the industry

- Slope Forward (Slope 7° to 30°)

- Slope Back (7° to 22°)

- Bullnose Slope Forward (7° to 30°)

- Bullnose Slope Back (7° to 30°)

- Flat Top

Single 316 SS Three-Point Latching

- Hygienic quarter turn

- Master Defeater and Slave handlessssss

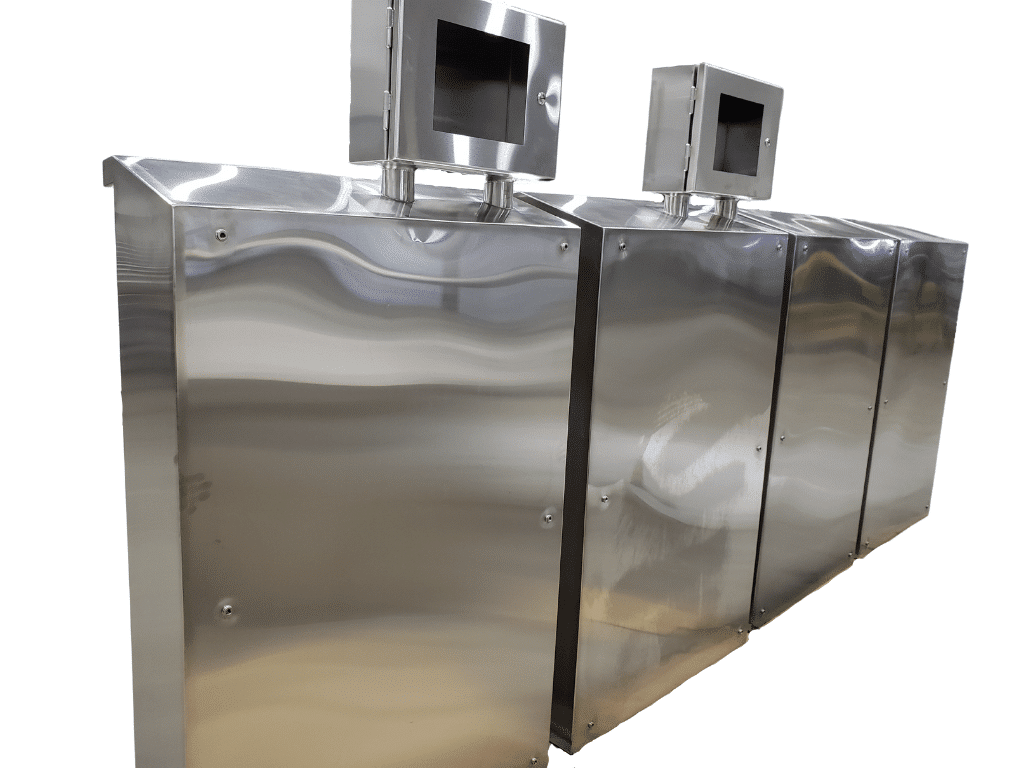

Limitless Features

Fully customize your flanged enclosure with limitless options including:

- External disconnect enclosure

- Hygienic Leg Assemblies – 316 SS material

- Sequester enclosure

- Trapped Key Interlock Exchanged Unit & Convenience Enclosure

- Heavy-Duty Lifting Eyes – 316 SS material

- Hygienic Windows: Polycarbonate, Acrylic, or Thermal – Type 4X, IP66, IP68, and IP69K rated

- Center divider available to separate low voltage from high voltage

- Grounding provisions are provided on all doors and enclosures

- Drilled and tapped back panels

- Back panels are available in 12 Gauge G90 Galvanized, Aluminum, Stainless Steel, and Powder Coated

- Hygienic Operator interface swivel arm assemblies – Type: 4X, IP66, IP68, and IP69K

- Floor mount configuration

- Double Stud® hygienic mounting brackets: Bolt-on 1, 2, 4 & 10” off wall

- Double Stud® hygienic mounting extensions: 1, 2, and 3”

Limitless Features

Fully customize your flanged enclosure with limitless options including:

- External disconnect

- Hygienic Leg Assemblies – 316 SS material

- Sequester enclosure

- Trapped Key Interlock Exchanged Unit & Convenience Enclosure

- Heavy-Duty Lifting Eyes – 316 SS material

- Hygienic Windows: Polycarbonate, Acrylic, or Thermal – Type 4X, IP66, IP68, and IP69K rated

- Center divider available to separate low voltage from high voltage

- Grounding provisions are provided on all doors and enclosures

- Drilled and tapped back panels

- Back panels are available in 12 Gauge G90 Galvanized, Aluminum, Stainless Steel, and Powder Coated

- Hygienic Operator interface swivel arm assemblies – Type: 4X, IP66, IP68, and IP69K

- Floor mount configuration

- Double Stud® hygienic mounting brackets: Bolt-on 1, 2, 4 & 10” off wall

- Double Stud® hygienic mounting extensions: 1, 2, and 3”

Enclosures for All Industries

A solution that meets the demands of all industries. From heavy industry to high-tech laboratories, our flanged enclosures are designed to meet the unique challenges of your electrical equipment.

Enclosures for All Industries

A solution that meets the demands of all industries. From heavy industry to high-tech laboratories, our flanged enclosures are designed to meet the unique challenges of your electrical equipment.

Locations of disconnects and requirements for proper disconnect spacing is to be determined by purchaser. Consult Space Occupied by Disconnect drawing to determine whether or not the disconnect device you are using will fit the enclosure size that you have selected for the application.

Refer to the current National Electrical Code 2008 article 430.10(B) for wiring space required for size of conductors to be connected to disconnect. Always verify your application to determine if wiring space is adequate prior to drawing approvals. Custom Stainless Enclosures, Inc. is not responsible for verifying flange design, with customers disconnect and or enclosure sizes.